C Connect s.r.o. offers its customers laminating, which is the process of applying different materials on a substrate with the use of heat or adhesive tape. The final product may then have the desired properties: strength, surface, appearance, etc.

Laminating is usually the first operation in the further processing of finished materials. During or after

lamination we can divide the resulting material into coils of the desired width or into formats as required.

Coil rewinding is also commonly offered.

Laminated products or semi-products are used in many fields:

- Automotive

- Appliances

- Building industry

- Packaging

C Connect s.r.o. uses and offers the following lamination methods:

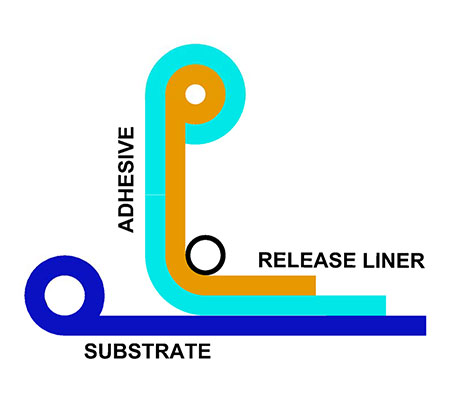

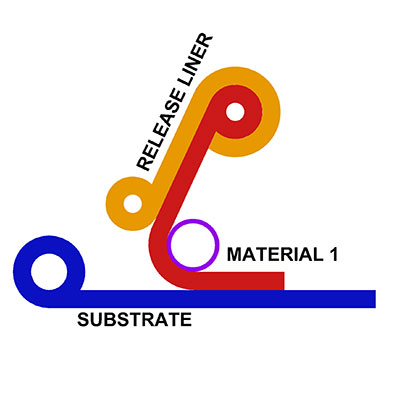

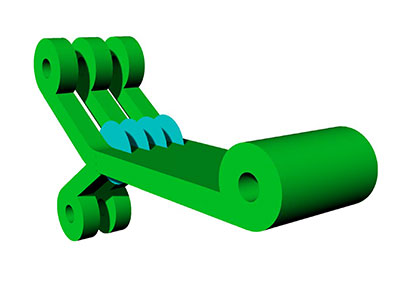

SINGLE-SIDED LAMINATION OF SECOND LAYER

Material with a PSA (Pressure Sensitive Adhesive) adhesivelayer is laminated on one side of the substrate.

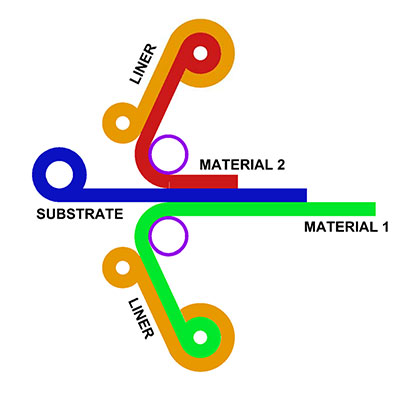

DOUBLE-SIDED LAMINATION

Material with a PSA adhesive layer is laminated on both sides(top and bottom) of the substrate.

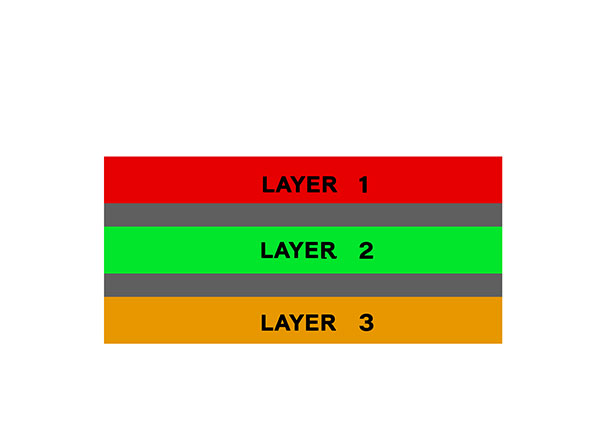

MULTI-LAYERED LAMINATION

We can laminate a layer onto another layer.

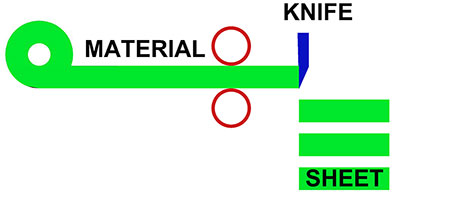

SHEETING

The material is transversally cut into formats.

SLITTERING

The material is longitudinally cut into coils of the desired width.

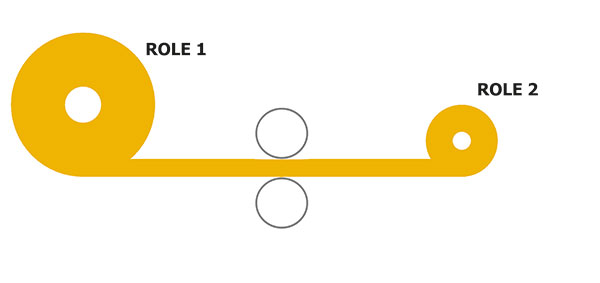

REWINDING

The material is rewound from roll to roll, for example, to obtaina smaller diameter roll or to tighten / loosen the original roll.

ADHESIVE TAPE LAMINATION

The basis for laminating is the application of an adhesive tape to a substrate. The tape with a PSA adhesive is applied on the bottom/top side of substrate. After removal of the protective layer – release liner, the substrate can be glued to the required place with the demanded side on the top.Tape structure

Liner: PE, PP, PES, FOAM

Adhesive: SILICON, ACRYLIC, RUBBER, HOT-MELT

Carrier: FILM, NONWOVEN, PAPER, TISSUE